From Automotive Manufacturer to Battery Innovation Leader

Starting back in 2005 as a company focused on batteries for consumer electronics, BYD eventually shifted gears toward electric vehicles after making significant investments in research and development. This move paid off big time, and by 2023, BYD had become the biggest electric car manufacturer in China. Their batteries are now found in about a quarter of all electric vehicles across the country. What sets them apart from many rivals is their unique approach to design. While other companies rely heavily on outside suppliers, BYD has developed an integrated system where they can work on improving both battery capacity, which goes up to around 150 kWh, and how well cars cut through air at the same time. This gives them a real advantage in the market.

Integration of Vertical Supply Chain in BYD Cars’ Operations

BYD has control over about 90% of what goes into making their cars, starting right from where they dig out lithium all the way through to putting together finished vehicles at the end of the line. Their approach is pretty unique when it comes to car manufacturing these days. The company runs its own chip factory too, churning out around 50 thousand IGBTs each day. These are those special semiconductors used in electric vehicles. This setup cuts down on delays that usually happen with regular suppliers, maybe saving them something like 40% in time lost waiting for parts. And financially speaking, this whole system saves roughly three thousand two hundred dollars per vehicle produced. Plus, there's another benefit nobody talks about much but matters a lot: quality control. Defects? Well, BYD manages to keep those problems happening only about a third as often as most other manufacturers do across the board.

Strategic Shift Toward In-House Battery Development

In 2018, BYD stopped buying batteries from outside suppliers and started putting around $1.4 billion every year into developing their own battery cells. This strategic shift led to an impressive number of innovations, with 127 new patents filed specifically for battery thermal management from 2020 through 2023. By taking control of their power systems, the company can now customize lithium iron phosphate (LFP) battery chemistry for different car models. The results speak for themselves: these custom batteries charge about 22% quicker and pack 15% more energy per unit volume compared to what they used to get from external manufacturers. This level of customization gives BYD a real edge in the competitive EV market.

Blade Battery Technology: Redefining Safety and Efficiency in BYD Cars

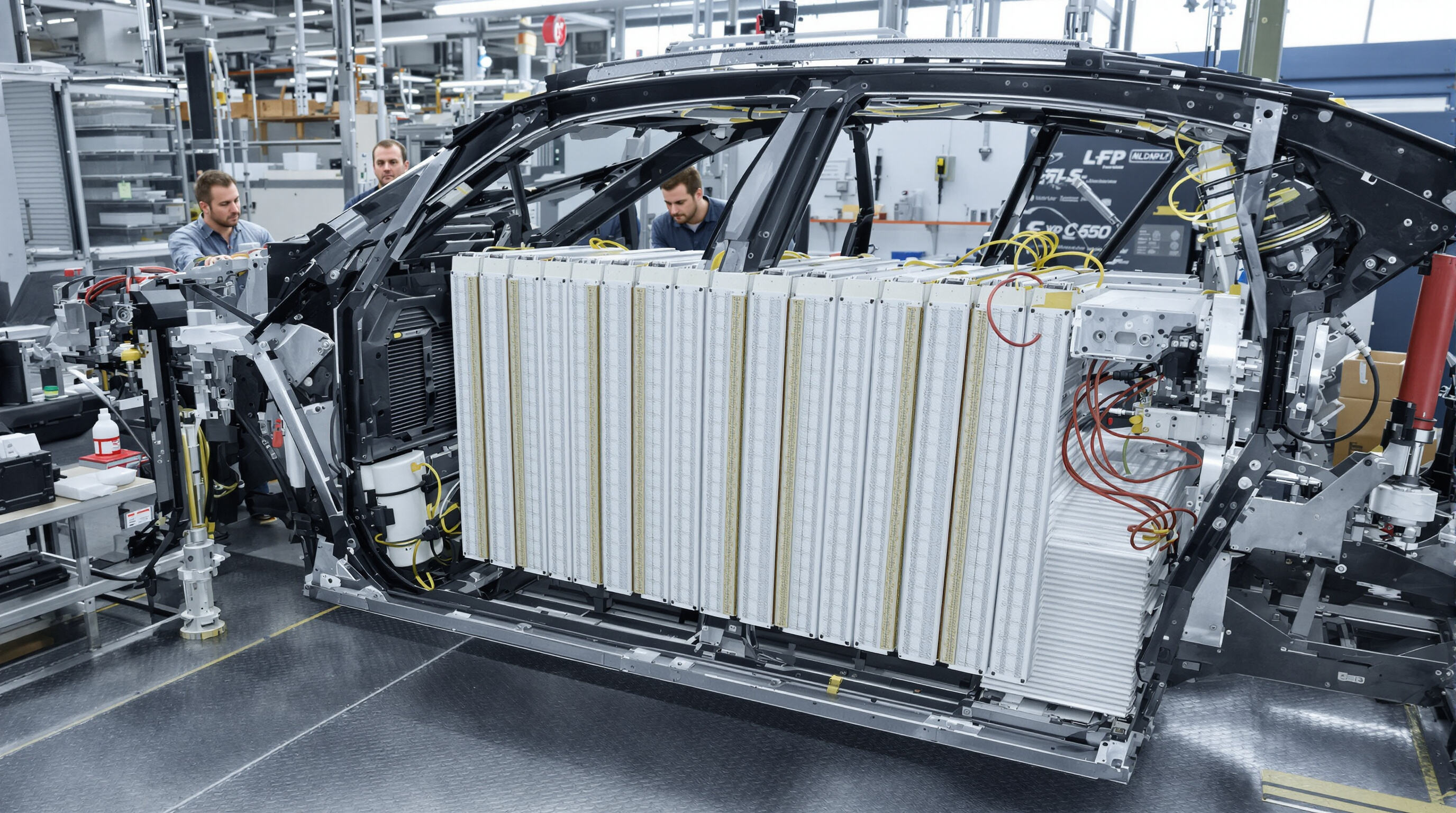

Understanding the Structural Design of the Blade Battery

The BYD Blade Battery is changing how we think about storing energy thanks to its special lithium iron phosphate chemistry and an innovative structural approach. Instead of the usual prismatic or cylindrical cell designs, this battery stacks super thin LFP cells vertically in what looks like rows of blades. The result? About 50% more space efficiency inside the battery pack than what we see in traditional setups. What makes it really interesting is how the battery actually becomes part of the car's frame itself. This integration makes the whole vehicle stronger structurally but also lighter at the same time something that matters a lot when talking about getting better range out of electric vehicles.

Puncture Test Performance and Thermal Stability Advantages

BYD put the Blade Battery through some serious stress tests to prove how safe it really is. They did things like poking nails through it and crushing it, which sounds crazy but that's what happens in real accidents. What they found was pretty impressive: even after being punctured, the Blade Battery packs didn't produce any smoke or catch fire at all. The temperature stayed cool too, never going above 60 degrees Celsius on the surface. Compare that to regular nickel-manganese-cobalt batteries, which got way hotter than that same test situation, sometimes reaching over 500 degrees! This shows why lithium iron phosphate chemistry has such good heat resistance properties. All these findings are laid out in detail in BYD's 2024 safety report for the Blade Battery, and they make a strong case for why this technology could help prevent dangerous fires in electric vehicles.

Comparison Between Traditional NMC and LFP Blade Batteries

While NMC batteries prioritize energy density, BYD’s LFP-based Blade Battery offers distinct advantages:

| Metric | Blade Battery (LFP) | Traditional NMC |

|---|---|---|

| Cycle Life (80% capacity) | 3,000+ charges | 1,000–1,500 charges |

| Thermal Runaway Risk | Minimal (<60°C post-puncture) | High (>500°C post-puncture) |

| Cobalt/Nickel Dependency | None | Required |

This shift reduces reliance on scarce metals and lowers production costs by 15–20%, aligning with sustainable manufacturing goals.

Simplifying Architecture to Reduce Battery Defects

The way BYD puts together its batteries from start to finish cuts down on complicated assembly steps, which has helped slash defects by around 30% when compared with batteries built using separate modules. When they removed those extra parts like electrical connectors and metal supports, the whole design became much simpler for the Blade Battery. This simplicity just makes sense because there are fewer things that can go wrong inside the battery pack itself. And let's not forget about their smart quality checks powered by artificial intelligence. These systems keep defect rates below 5 out of every million cells stacked together – something most electric vehicle manufacturers would kill for in their own factories.

Maximizing Longevity and Real-World Performance in BYD Cars' Batteries

Cycle Life Exceeding 3,000 Charges with LFP Chemistry

BYD has been using lithium iron phosphate (LFP) chemistry for their batteries, getting them to last well beyond 3,000 full charge cycles. That's roughly equivalent to driving over a million kilometers before needing replacement. Compare this to the older nickel-manganese-cobalt (NMC) batteries that usually start showing signs of wear after around 2,000 cycles. What makes LFP so good? Well, these batteries handle heat better and put less strain on themselves while charging. As a result, they lose only about 2% of their capacity each year, which is pretty impressive when looking at long term performance.

Battery Performance Under Real-World Driving Conditions

Field tests indicate that BYD battery packs still hold around 92% of their original capacity after five years when used in normal weather conditions, dropping slightly to about 88% in areas with harsh temperatures. The company's special temperature control tech keeps things running smoothly between -30 degrees Celsius and 60 degrees Celsius. This helps avoid problems like lithium plating when it gets too cold and stops electrolyte breakdown during heatwaves. When it comes to how much energy they actually use, these batteries perform pretty consistently no matter what kind of road they're on. Even when climbing hills and mountains, drivers only lose roughly 5% of their expected range compared to driving on flat roads.

AI-Optimized Manufacturing for Consistent Battery Quality

Modern neural network technology now checks over 2,300 different factors throughout the cell manufacturing process, spotting tiny flaws in how thick the electrode coatings are applied at the micron level. The implementation of this artificial intelligence system has cut down on defective batteries by about forty percent since early 2022. At the same time, it's made the energy density much more consistent between cells, bringing variation down to just under one percent. When paired with those new automated systems that can fix themselves during electrolyte injection, these manufacturing techniques actually extend battery life expectancy by around twenty percent when compared against traditional ways of putting batteries together.

Extending Range and Efficiency Through Smart Battery Design

Pack-to-Cell Efficiency Breakthroughs in BYD Cars' Design

BYD's pack-to-cell design cuts down on unnecessary casing components, which saves around 27% of previously wasted space while making the whole structure sturdier. With this all-in-one setup, they've managed to boost energy density up to 360 Wh per liter. That means getting about 20% extra battery power without needing more room inside vehicles than traditional battery packs require. The cleaner layout also helps reduce spots where electricity might get stuck as it moves through the system. Less resistance translates into cooler operation when someone slams on fast charging, something that becomes really important for electric cars trying to recharge quickly at highway rest stops.

Achieving 600+ km Range in Dynasty Series Models

Testing on actual roads shows that the BYD Seal sedan can go around 610 kilometers when it's about 25 degrees Celsius outside. There's usually about a 5 percent difference compared to what happens in controlled laboratory settings versus real highway driving. The car has these fancy battery preparation systems that keep the electrolyte just right so it doesn't get too thick or thin. This helps preserve most of the range even during cold weather, maintaining roughly 78 percent of its normal range down to minus 15 degrees Celsius. Independent researchers have looked into this too, and their findings back up what BYD claims. After covering 50 thousand kilometers through city traffic where cars constantly start and stop, the battery only loses less than 2 percent of its total capacity according to these tests.

Balancing Lightweight Design with Structural Integrity

The BYD battery packs feature 7 series aluminum alloy honeycomb structures which cut down on overall weight by around 19 kilograms when compared to traditional steel frames. Their proprietary carbon fiber reinforced separators are pretty impressive too, holding up against 18 MPa of sideways pressure without messing with the ions' ability to conduct electricity properly. From a materials standpoint, this represents a significant advancement. The result? A weight savings of approximately 13 percent per kilowatt hour while still meeting those tough ECE R100 safety requirements for crash resistance during collisions at speeds up to 70 kilometers per hour. Manufacturers really need these kinds of innovations as they strive to make electric vehicles both lighter and safer without sacrificing performance.

Cold Weather Performance and Charging Innovations for BYD Cars

Thermal Management for Reliable Battery Performance in Cold Climates

The thermal management system from BYD tackles the common problem of reduced battery range when lithium-ion batteries are exposed to freezing weather. Most electric vehicles suffer around a 40% drop in driving range during cold conditions, but BYD has incorporated special phase change materials (PCM) into their design to better control how heat spreads throughout the battery pack. Research conducted by third parties shows these materials actually cut down peak temperature fluctuations by about 17.7 degrees Celsius even in really harsh winter environments, allowing the vehicle to keep running smoothly at temperatures as low as minus 20 degrees Celsius. What makes this technology particularly effective is that it stops the battery electrolyte from freezing solid, which would otherwise damage the cells, while also cutting back on all that extra power normally needed just to warm up the battery before driving.

Fast Charging with Minimal Degradation

The automaker’s cold-weather charging innovations include electrode architectures that sustain 6C fast-charging rates at -10°C–double the speed of conventional systems–without lithium plating or capacity fade. Research shows this approach retains 95% charge capacity after 3,000 cycles, achieved through 3D-structured anodes and artificial solid-electrolyte interfaces.

Regenerative Heating Systems to Preserve Winter Range

A neural-network-controlled system recaptures waste heat from motors and power electronics, reducing cabin heating energy drain by 32%. Combined with self-heating battery modules that activate during parking, this extends real-world winter range to within 12% of fair-weather performance metrics.

FAQ Section

Why did BYD stop using external battery suppliers?

BYD shifted from external suppliers to in-house battery development in 2018 to gain control over their battery production, allowing them to customize lithium iron phosphate (LFP) battery chemistry for different car models. This move led to faster charging times and increased energy density compared to external batteries.

How does BYD ensure battery safety?

BYD conducts rigorous stress tests, such as puncture tests on their Blade Battery, to demonstrate safety. The Blade Battery's lithium iron phosphate chemistry provides superior thermal stability, preventing fire risks even under extreme conditions.

What is the advantage of BYD's vertical supply chain integration?

BYD's vertical supply chain integration allows them to control nearly 90% of their car manufacturing processes, reducing delays and defects while saving costs on each vehicle. It also enhances quality control by minimizing defects.

Does BYD's Blade Battery require cobalt or nickel?

No, the Blade Battery is based on lithium iron phosphate chemistry, which eliminates the need for cobalt or nickel, aligning with sustainable manufacturing practices.

Table of Contents

- From Automotive Manufacturer to Battery Innovation Leader

- Integration of Vertical Supply Chain in BYD Cars’ Operations

- Strategic Shift Toward In-House Battery Development

- Blade Battery Technology: Redefining Safety and Efficiency in BYD Cars

- Maximizing Longevity and Real-World Performance in BYD Cars' Batteries

- Extending Range and Efficiency Through Smart Battery Design

- Cold Weather Performance and Charging Innovations for BYD Cars

- FAQ Section